Digested Organics Case Study

Nutrient Concentration & Water Reclamation Case Study

System Description

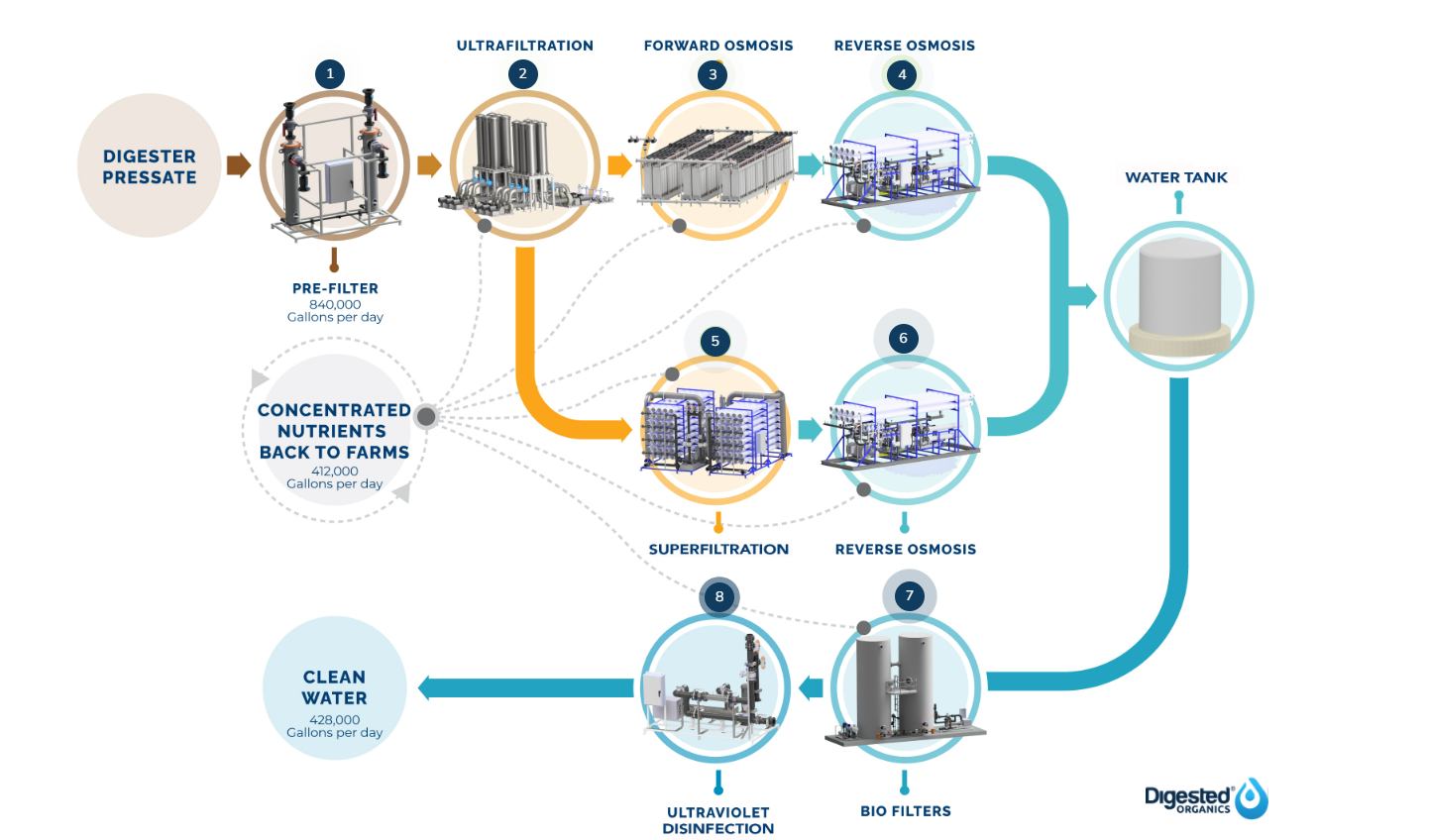

The combined anaerobic digester and water filtration system aids in reducing phosphorus runoff and improving farming practices for the participating Wisconsin dairy farms. Unlike other methane digesters, the water filtration technology makes BC Organics unique. The process uses several steps of filtration to convert digested manure into nutrient-rich concentrates and clean water.

The slurry is processed via ultrafiltration to remove suspended solids and then a combination of superfiltration, forward osmosis and reverse osmosis to make water clean enough to drink.

Raw, screened, or filtered liquid is first passed through Porifera’s Forward Osmosis (PFO) membrane stacks, where 50-95% of the water is removed by passing through the membrane and into a salt water solution. The concentrate exits the FO system and can be collected in a tank nearby. The salt water is then processed by RO membranes to generate clean water and brine. The brine is passed back through the FO system continuously. Clean water is continuously discharged from the RO system and can be stored onsite for reuse or discharged.

Application

Porifera’s forward osmosis systems are in operation at the world’s largest manure biogas processing facility in Greenleaf, Wisconsin.

The BC Organics Nutrient Concentration & Water Reclamation (NCWR) Facility is a state-of-the-art treatment plant utilizing unique membrane filtration equipment to process nearly 1,000,000 gallons per day of digested dairy manure and return over 400,000 gallons per day of clean water to the environment. The 13 contributing farms and over 35,000 cows send nearly 1 million gallons of manure per day for processing into 16 anaerobic digester tanks to capture methane and create 1,630 MMBtu’s of renewable natural gas per day.

Raw manure from local dairy farms is pumped and trucked to the facility for digestion in 16 above ground tanks, capturing methane which is purified and injected into nearby natural gas pipelines as Renewable Natural Gas.

Benefits

Following this process, the liquid digestate is screw-pressed and dried for fiber bedding. The pressed liquid from this process flows into the Nutrient Concentration and Water Reclamation/NCWR) system by Digested Organics, which produces and discharges over 400,000 gallons of clean water every day.

By removing nearly half of the digestate volume as clean water, the facility helps reduce the number of trucks moving digestate and minimizes the volume of material participating farms have to lagoon store and then land apply each year. Since the farms receive back more concentrated liquid digestate, they save money on land application, can use the liquid fertilizer in a more targeted fashion when needed (thereby helping to reduce runoff), and haul it to fields further away that traditionally receive less manure-based fertilizer. The farmers are able to haul drier, lighter, material to provide the same enrichment to the soil, which enables a reduction of 50-60% of water demand on the fields.